- Mineral Separator[10]

- Brick Making Machinery[10]

- Crusher[10]

- Mine Mill[6]

- Cement Making Machinery[2]

- Drying Equipment[7]

- Other Refrigeration & Heat Exchange Equipment[1]

- Mining Feeder[1]

- Vibrating Screen[1]

- Other Construction Machinery[1]

- Other Construction Material Making Machinery[1]

- Pressure Vessels[1]

- Moulds[2]

- Cast & Forged[1]

- Other Industrial Filtration Equipment[1]

- Contact Person : Ms. Bai Jenny

- Company Name : Henan Bochuang Machinery Equipment Manufacturing Co., Ltd.

- Tel : 86-371-86638099

- Fax : 86-371-86638236

- Address : Henan,Zhengzhou,Dali Village, Xiliuhu Management Office, East Section of Zhengshang Road, Zhongyuan District, Zhengzhou City

- Country/Region : China

- Zip : 450000

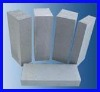

aac block

AAC Block

The following is the detail information of aac block making process and brief introduction of aac production line.

Autoclaved Aerated Concrete Production Line

The aerocrete produces the technological process:1. The raw materials store in the material storehouse (or stores the pot) after dealing with reserve such as lime, cement, gypsum, sand (or fly ash)2. Aluminum powder or aluminum lotion is through dealing with the reserve material for use3. Raw materials measure according to certain matching by electron balance measure, aluminum powder, water put into aluminum powder mixer is it is it suspend the liquid to make to mix after measuring4. The batching water (cold water or hot water pitcher hot water) is measured by the electronic water balance 5. Put into and pour among the mixers in certain order after, raw materials, aluminum powder suspend the liquid is measured, pour and enter the mould after mixing evenly (panel should be put network slice of reinforcing bar in advance in the mould)6. Quiet to is it raise in advance to park through certain temperature and time, is it transport to the cutting machine to hang from upset hoist upset 90° after the base body reaches certain intensity, the drawing of patterns is cuta. The base body carries on the side and cuts and mills the trough verticallyat firstb. Then carry on the vertical level to cutc. Cut horizontally finallyd. Cut good base body, raises to cauldron car go on one yard of shelves organize into groups to steam to transport to hang to drive a vehicle to load7. Raise products well, produce after the cauldron breaking the board off with the fingers and thumb by the board breaking off with the fingers and thumb machine to steam8. Pile from finished product hoist or forklift to finished product field pile the buttress according to specification to carry9. Steaming and raising the car and side board and entering the next board of circulation and returning after, the finished product is unloaded, with upset hoist mould frame association that drawing of patterns get off, restore 90°return to pour mixer pour again after clearing up

We have many Chinese customers and have a few foreign customers with rich experience. We can make the equipment configuration, give the professional advice and provide the technical support according to clients' different requirements. If you want to invest a potential industry and get more profit, aac plant is a best choice for you. Earlier you start, more profit you will get. Our company can be your strong support.

Contact person: Jenny

Director of International Trade Depatment

Henan Bochuang Machinery Equipment Manufacturer Co.,Ltd

Tel:+86-371-86638236 +86-15838150898

Fax: +86-371-86638233

Skype: gybaige

aac block